Center for Large Structure Production

A landmark for innovation

We think it’s a fantastic looking building that matches our needs while helping to redeem the huge potential of the LSP project. We believe that the beautiful architecture and clear references to SDU in Odense will make it a landmark that also points to new chapters in SDU’s and Funen’s robotics adventures.

Jens Ringsmose, Rector of the University of Southern Denmark.

The center will research and develop automated solutions to build large-scale structures such as wind turbines, ships, and structures for construction. With the building the activities can unfold to their full potential, allowing researchers and companies to develop robots for large-scale structures – robots that do not exist on that scale today.

Diverse Innovation

The robotics center will serve as a landmark for the transformation of the maritime sector, construction, energy sectors, and the robotics industry. Its rusty-red mixed perforated façade makes a tectonically dynamic impression while preserving strong references to both the existing industrial buildings at Lindø and SDU, which creates a striking arrival at the Port and Odense.

In the judge’s motivation, it is stated that the building will heighten the overall building quality of the old shipyard area. The building will house robots and technological equipment as well as students, researchers, and companies.

The Architectural Concept

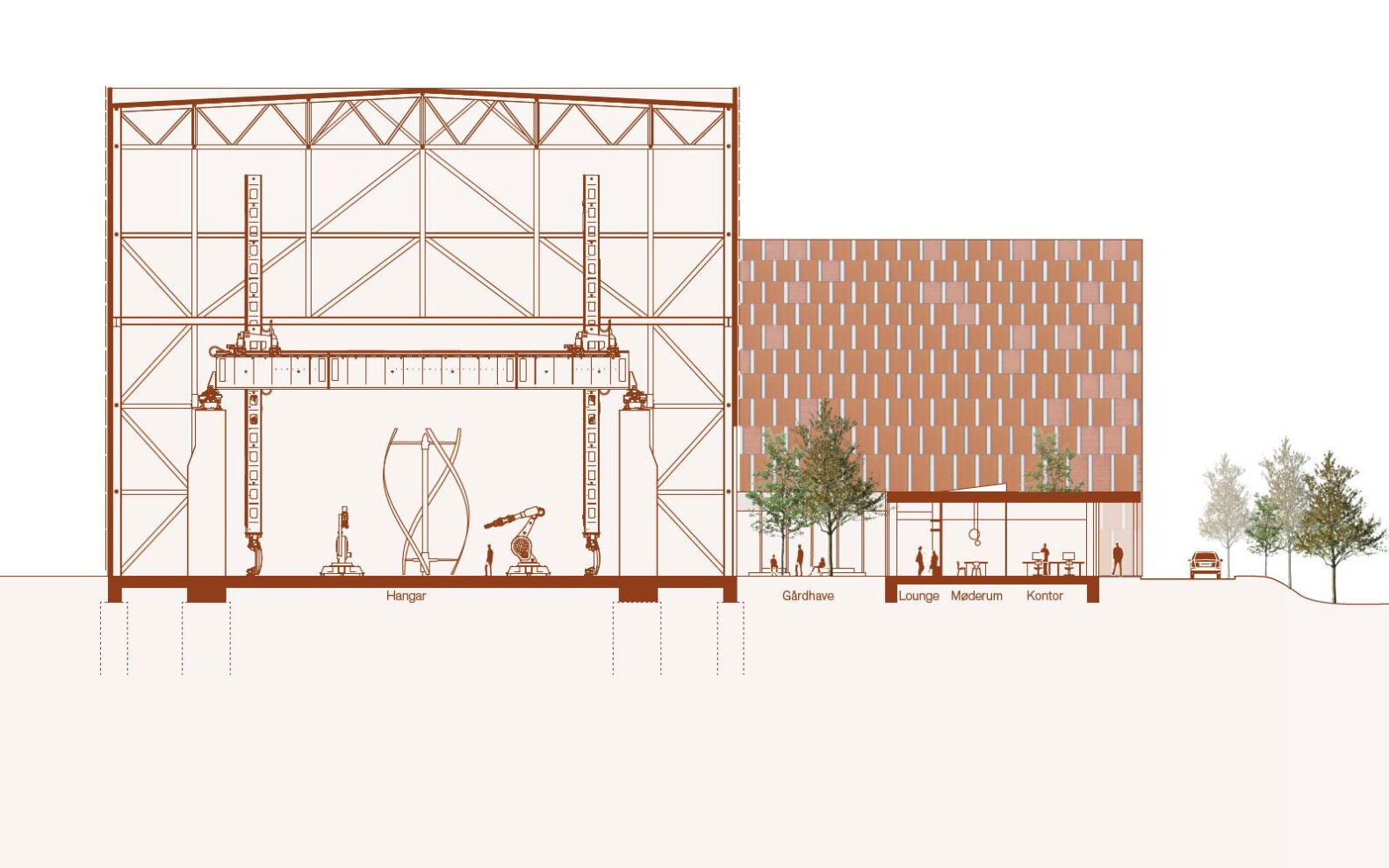

Our project comprises three buildings under one unifying membrane: the façade. We have chosen this approach to unite the diverse requirements of the building’s functions so that the LSP center is perceived as one cohesive and distinctive building.

Compositionally, we use the distinct and contrasting heights of the three buildings; Hangar, Warehouse, and Administration, to create a varied but cohesive sculptural volume, with the potential to become a natural landmark in the landscape.

Optimizing Flow and Connectivity

In the layout, it has been pivotal that the production track from the maneuvering area to the Platform and further into the Hangar is a continuous and straight path. Platform 1, the hangar and warehouse form a simple and logical movement triangle with the large doors close to each other. For example, the warehouse is placed as a nearby annex to Platform 1 so that equipment, models, or similar can be easily placed or redistributed to and from the Hangar. By moving the warehouse’s location slightly towards the south, space is created for the access road to the general parking to be led away from the platform and behind the warehouse. In this way, we avoid crossing traffic and create easily readable logistics on-site.

The administration is placed on one level alongside the hangar towards the east. Here, there are good opportunities for direct contact with the hangar, while creating a covered connection to the warehouse. The administration building itself becomes an elastic building in expression, reaching out and holding on to the large volumes; the hangar and the warehouse, and thus tying the entire building complex together. While embracing the function’s enormous scale in the exterior, we break down the scale in the interior and create experiential spaces for the human scale.

Developing Robots

There will be a focus on researching and developing automated solutions for the construction of large structures such as wind turbines, ships, and buildings. Thanks to the center, activities can be conducted thoroughly, providing researchers and companies with the opportunity to develop robots for large structures. Robots that do not currently exist at that scale.

- Client

- University of Southern Denmark

- Area

- The building is 3 100 m2 / 33 368 ft2, the landscape is 5 900 m2 / 63 507 ft2

- Year

- 2025

- Location

- Odense, Denmark

- Collaborators

- ISC Consulting Engineers / 1:1 landskab

- Funding

- The center is established as part of the Maersk Mc-Kinney Moller Institute and has received funding from the A. P. Møller Foundation

- Images

- Exterior renders by Theodor Fritz